Process Inefficiencies

Inefficient processes hinder productivity and drive up operational costs. Identifying and rectifying bottlenecks is crucial for maintaining a competitive edge.

Maintaining a competitive edge in the fiercely competitive manufacturing landscape is no longer a mere aspiration; it's an imperative. Iwoscan — a transformative solution meticulously engineered to enhance and optimise your manufacturing operations.

Integracija su Odoo ERP

Integracija su Odoo ERP Integruotas užduočių skaidymas ir sujungimas

Integruotas užduočių skaidymas ir sujungimas Neiškraipyti pirminiai duomenys

Neiškraipyti pirminiai duomenys

Discover how Iwoscan's innovative features and benefits are designed to transform performance manufacturing, enhancing efficiency, quality, and overall productivity.

Iwoscan funkcionalumas suteikia jūsų verslui tikslumą, saugumą bei išsamias įžvalgas, užtikrinant, kad išliktumėte inovacijų priešakyje.

Procesų stebėjimas realiuju laiku, veiksmingas anomalijų identifikavimas ir problemų sprendimas. Patogi vartotojo sąsaja bei procesų optimizavimas.

Optimizuokite savo veiklą įgyvendindami darbuotojų produktyvumo stebėseną, gamybos anomalijų sekimą bei didindami kokybės kontrolės efektyvumą.

Prieiga prie svarbių duomenų ir analitikos. Priimkite greitus sprendimus ir tiksliai vertinkite veiklos rezultatus.

Duomenų saugumas. Jūsų informacija saugoma įrenginyje iki dvejų metų.

Paprasta komunikacija su darbuotojais. Tobulinkite grįžtamąjį ryšį, apdovanojimo už gerus rezultatus sistemas bei nuolatinio tobulėjimo modelius.

Intuityvi sąsaja užtikrina lengvą procesų optimizavimą, o ryškus LED ekranas suteikia geresnį matomumą.

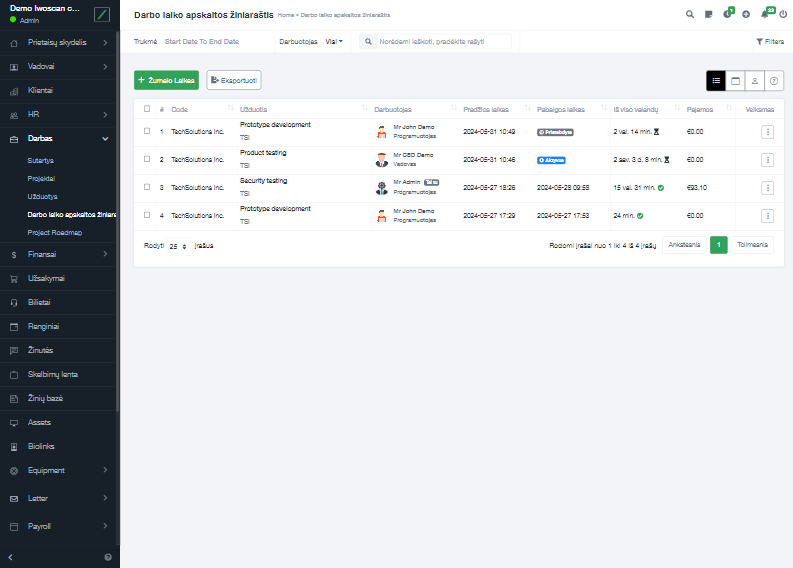

Duomenų eksporto formatai: CSV, JSON, HTML ir binaris formatas. Be to, galite generuoti ataskaitas tiesiogiai savo interneto naršyklėje arba atsisiųsti neapdorotus duomenis .csv formatu.

Maksimaliai padidinkite efektyvumą naudodami integruotą teksto įvestį įvykiams registruoti, tikslų laiką su laikrodžio funkcija ir universalų duomenų fiksavimą su įmontuotu brūkšninių kodų skaitytuvu bei RFID galimybėmis, užtikrinančiomis sklandžią veiklą ir išsamų įvykių sekimą.

Wi-Fi jungtis, supaprastintą įrenginio nustatymus bei valdymą, o interaktyvios ataskaitų suvestinės suteikia tikslias įžvalgas, leidžiančias padidinti veiklos efektyvumą, maksimaliai išnaudojant vartotojo sąsają.

Mūsų sistema veikia savarankiškai, užtikrindama, kad pagrindiniai duomenų apdorojimo procesai nepriklauso nuo išorinių serverių, taip garantuodama jūsų duomenų saugumą ir prieinamumą.

In the realm of employee engagement, disconnect poses a significant challenge, impacting morale and productivity. Explore how Iwoscan, your dedicated Employee Engagement Enhancement Partner, tackles key issues, boosts motivation, and nurtures a thriving workplace.

Inefficient processes hinder productivity and drive up operational costs. Identifying and rectifying bottlenecks is crucial for maintaining a competitive edge.

Maintaining consistent product quality can be challenging, leading to defects and customer dissatisfaction. Precision quality control is essential for reputation and market success.

Excessive downtime disrupts production schedules and impacts profitability. Minimizing downtime is critical for maximizing manufacturing output.

Managing vast amounts of manufacturing data can be overwhelming and prone to errors. Streamlining data management and analysis is key for informed decision-making.

Ensuring that your workforce has the right skills is essential for efficiency and product quality. Identifying and addressing skill gaps is vital for long-term success.

Įsivaizduokite realybę, kur gamybos efektyvumas yra aukščiausiame lygyje, bei precizinis produktyvumas. Iwoscan pritaikomumas gamyboje suteiks jums pranašumą konkurencinėje kovoje.

Siekime gamybos aukštumų kartu!

Iwoscan is primarily designed to optimise and enhance performance manufacturing processes. It offers real-time monitoring, data analysis, and quality control solutions to improve efficiency, reduce costs, and enhance product quality.

Iwoscan provides real-time insights into manufacturing processes, helping identify bottlenecks, inefficiencies, and areas for improvement. This information empowers you to streamline operations and boost overall efficiency.

Iwoscan is versatile and adaptable, making it suitable for various industries, including automotive, electronics, aerospace, and more. It seamlessly integrates into different manufacturing environments.

Iwoscan ensures precision quality control through real-time data analysis. It detects defects early in production, reducing the chances of subpar products reaching the market.

Yes, Iwoscan minimises downtime by providing real-time alerts and insights into potential issues. This proactive approach helps you take corrective actions swiftly, reducing production interruptions.

Iwoscan is designed with user-friendliness in mind. Its intuitive interface makes it accessible to both technical and non-technical personnel. Training requirements are minimal.

Iwoscan prioritises data security. It offers secure data storage on the device for up to 2 years, reducing reliance on external servers for critical data processing and ensuring the safety of your manufacturing data.

Iwoscan is versatile and adaptable, making it suitable for various industries, including automotive, electronics, aerospace, and more. It seamlessly integrates into different manufacturing environments.

Iwoscan is adaptable and can be customised to fit the unique needs of your manufacturing processes. It's designed to enhance your specific manufacturing environment.

By implementing Iwoscan, you can expect improvements in manufacturing efficiency, product quality, cost reduction, and overall competitiveness. It helps you stay at the forefront of performance manufacturing.