Adaptability to Unforeseen Events

Manufacturing downtime leads to substantial financial losses, averaging $260,000 per hour, necessitating real-time monitoring and early intervention provided by Iwoscan to prevent costly disruptions.

Understand the pivotal role of Iwoscan in achieving task-splitting success, particularly in the seamless consolidation of subtasks, contributing to enhanced efficiency in manufacturing processes.

Integracija su Odoo ERP

Integracija su Odoo ERP Integruotas užduočių skaidymas ir sujungimas

Integruotas užduočių skaidymas ir sujungimas Neiškraipyti pirminiai duomenys

Neiškraipyti pirminiai duomenys

Iwoscan is the future of manufacturing defect detection, tracking, and analysis ally. We're not just a solution; we're your path to manufacturing excellence.

Iwoscan funkcionalumas suteikia jūsų verslui tikslumą, saugumą bei išsamias įžvalgas, užtikrinant, kad išliktumėte inovacijų priešakyje.

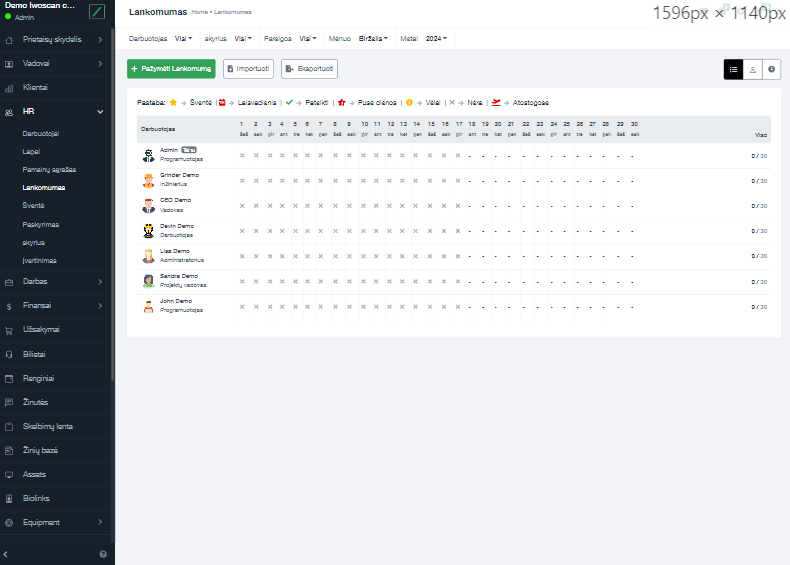

Procesų stebėjimas realiuju laiku, veiksmingas anomalijų identifikavimas ir problemų sprendimas. Patogi vartotojo sąsaja bei procesų optimizavimas.

Optimizuokite savo veiklą įgyvendindami darbuotojų produktyvumo stebėseną, gamybos anomalijų sekimą bei didindami kokybės kontrolės efektyvumą.

Prieiga prie svarbių duomenų ir analitikos. Priimkite greitus sprendimus ir tiksliai vertinkite veiklos rezultatus.

Duomenų saugumas. Jūsų informacija saugoma įrenginyje iki dvejų metų.

Paprasta komunikacija su darbuotojais. Tobulinkite grįžtamąjį ryšį, apdovanojimo už gerus rezultatus sistemas bei nuolatinio tobulėjimo modelius.

Intuityvi sąsaja užtikrina lengvą procesų optimizavimą, o ryškus LED ekranas suteikia geresnį matomumą.

Duomenų eksporto formatai: CSV, JSON, HTML ir binaris formatas. Be to, galite generuoti ataskaitas tiesiogiai savo interneto naršyklėje arba atsisiųsti neapdorotus duomenis .csv formatu.

Maksimaliai padidinkite efektyvumą naudodami integruotą teksto įvestį įvykiams registruoti, tikslų laiką su laikrodžio funkcija ir universalų duomenų fiksavimą su įmontuotu brūkšninių kodų skaitytuvu bei RFID galimybėmis, užtikrinančiomis sklandžią veiklą ir išsamų įvykių sekimą.

Wi-Fi jungtis, supaprastintą įrenginio nustatymus bei valdymą, o interaktyvios ataskaitų suvestinės suteikia tikslias įžvalgas, leidžiančias padidinti veiklos efektyvumą, maksimaliai išnaudojant vartotojo sąsają.

Mūsų sistema veikia savarankiškai, užtikrindama, kad pagrindiniai duomenų apdorojimo procesai nepriklauso nuo išorinių serverių, taip garantuodama jūsų duomenų saugumą ir prieinamumą.

"Splitting tasks" in the context of manufacturing and production lines refers to a strategic approach to manage and execute tasks more efficiently. This technique involves breaking down a larger task into smaller, manageable parts, each with instructions and timelines. The goal is to enhance flexibility, productivity, and adaptability in the manufacturing process. Here's an in-depth understanding of how task splitting benefits this domain.

Manufacturing downtime leads to substantial financial losses, averaging $260,000 per hour, necessitating real-time monitoring and early intervention provided by Iwoscan to prevent costly disruptions.

Frequent machine breakdowns disrupt production, costing up to 3% of annual revenue. Iwoscan's tracking and analysis enable proactive maintenance, reducing the impact of unplanned downtime.

Frequent equipment failures disrupt production schedules. Iwoscan's real-time monitoring and analysis detect issues early, allowing timely maintenance to prevent costly equipment breakdowns and downtime interruptions.

Operator errors reduce production efficiency. Iwoscan's tracking identifies operator-specific issues, enabling targeted training and performance improvements, ultimately minimizing operator-related challenges and production slowdowns.

Manufacturing schedules require precision, and task splitting provides a granular approach to scheduling. Whether a task needs to start, pause, or resume at specific times, this technique allows for accurate scheduling down to smaller increments, such as 15-minute intervals.

The ability to split tasks not only streamlines operations but also contributes to stress reduction. With everything under control and a more adaptable workflow, teams can focus on efficient production without the burden of constant rescheduling and adjustments.

Įsivaizduokite realybę, kur gamybos efektyvumas yra aukščiausiame lygyje, bei precizinis produktyvumas. Iwoscan pritaikomumas gamyboje suteiks jums pranašumą konkurencinėje kovoje.

Siekime gamybos aukštumų kartu!

Manufacturing defects refer to faults or imperfections in products or components that do not meet specified quality standards. They are a concern because they can lead to reduced product quality, increased production costs, and decreased customer satisfaction.

Iwoscan is a versatile tool designed to monitor various aspects of production processes. It can track and analyse manufacturing defects in real time, providing insights into when and where defects occur. This data helps businesses identify and address the root causes of defects, leading to improved product quality.

Iwoscan can be customised to detect and track defects, including dimensional inaccuracies, material flaws, assembly errors, and more. It can capture defect frequency, location, and severity data, allowing for targeted quality improvements.

Iwoscan helps reduce the need for costly rework, scrap, and warranty claims by promptly identifying and addressing manufacturing defects. This leads to cost savings and increased operational efficiency.

Yes, Iwoscan is designed for seamless integration into various manufacturing setups. It can be adapted to work alongside existing quality control measures and equipment, ensuring minimal disruption to production workflows.

Yes, Iwoscan's flexibility suits businesses of all sizes, from small-scale operations to extensive manufacturing facilities. It can be tailored to meet different organisations' needs and budget constraints.

Iwoscan is user-friendly and comes with comprehensive training and support. While some training may be necessary to maximise its potential, it is designed to be accessible to manufacturing teams with varying levels of technical expertise.

Businesses can expect improved product quality, reduced production costs, enhanced customer satisfaction, and greater operational efficiency. Iwoscan helps companies to achieve a defect-free manufacturing environment.

Yes, Iwoscan can complement existing quality control tools and methodologies. Its data can be integrated into broader quality management systems for a comprehensive defect monitoring and prevention approach.

The timeline for results can vary depending on the specific manufacturing processes and the extent of defects. However, many businesses report noticeable improvements in product quality and defect reduction shortly after implementing Iwoscan.